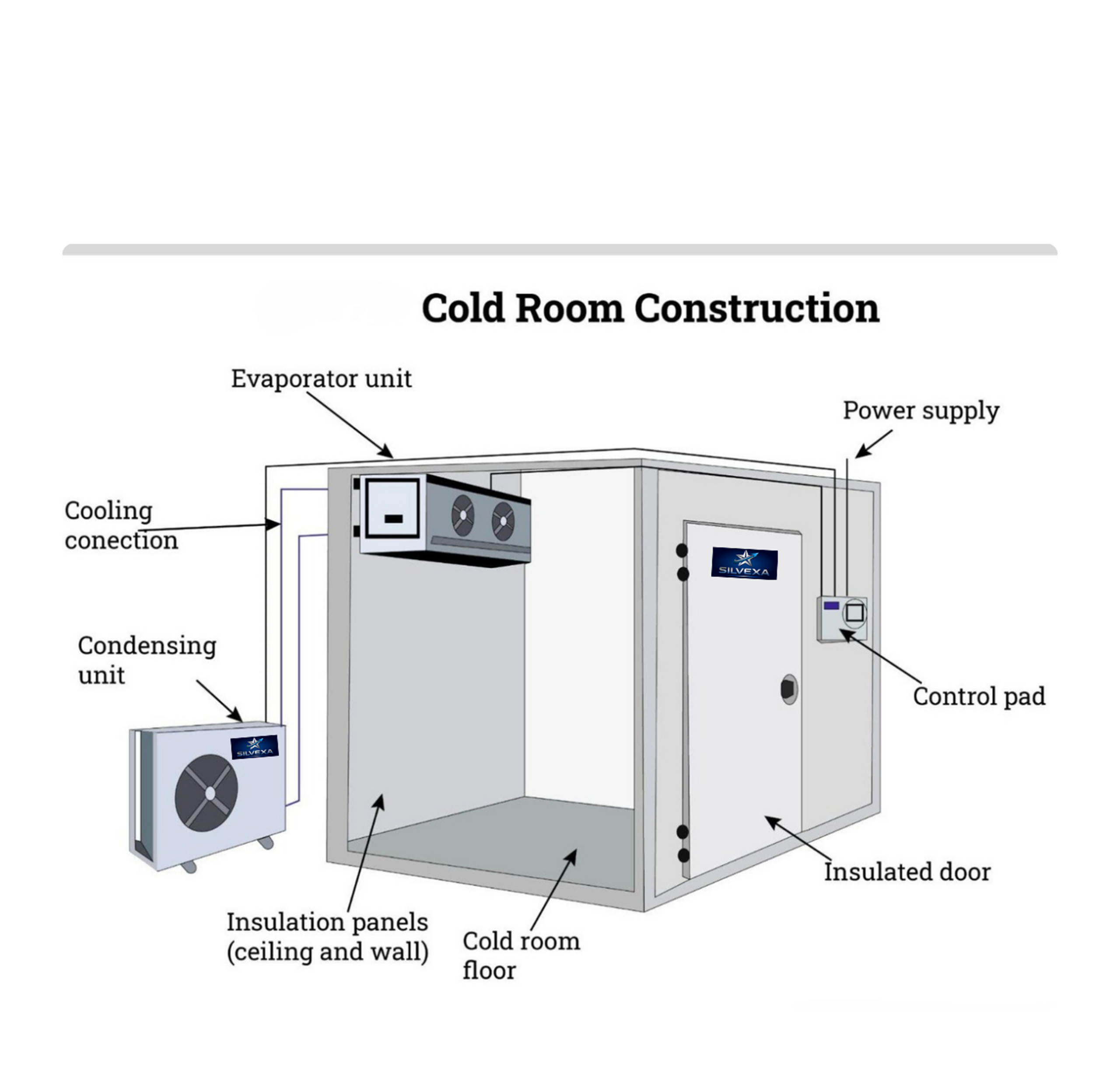

SILVEXA manufactures and installs premium Modular Cold Rooms designed for the specific storage needs of the food, pharmaceutical, and logistics industries. Unlike standard rooms, ours are built using high-density PUF panels that ensure excellent thermal insulation and reduced electricity consumption.

We use Eco-friendly PUF insulation with a density of 40–42 kg/m³. This ensures minimal heat transfer and maintains stable internal temperatures even when outside heat is extreme.

Our panels utilize a precision tongue-and-groove system with cam-locks. This ensures a completely airtight seal to prevent thermal leakage and allows for easy dismantling or expansion in the future.

Available in SS 304 or Pre-painted GI. Our surfaces are easy to clean and prevent bacterial growth, making them ideal for dairy and meat storage.

Every unit comes with built-in safety features including High/Low-Pressure (HP/LP) cutouts, oil protection switches, and phase protection to prevent compressor failure.

We start by analyzing your site conditions, product storage requirements, and daily throughput to understand your specific cooling needs.

Our engineering team performs precise Heat Load Calculations to select the exact machine capacity and insulation thickness required for maximum efficiency.

We execute the project using pre-fabricated modular panels and precision piping. Our cam-lock system ensures airtight assembly and rapid installation.

We conduct rigorous testing, including pressure tests and temperature pull-down trials, ensuring the system performs perfectly even at 52°C ambient temperature.

Our relationship continues after handover. We provide comprehensive AMC (Annual Maintenance Contracts) and 24/7 technical support.

Temperature Range:

Panel Thickness:

Density:

Cladding Material:

Floor Type:

Application: